© 2000-2023 - Enkey Magazine - All rights reserved

ENKEY SNC - VAT ID IT03202450924 / REA Code CA253701 - Phone. 078162719

5D printing has been the subject of much interest and speculation in the hi-tech world. Yet to the average consumer, 5D printing is still an alien concept. Ever since its debut, 3D printing of tridimensional, solid objects has been wildly successful, sparking a revolution in the entire manifacturing industry.

Its scope reaches well into our everyday experience. Indeed, many of the tools and items that we interact with have been entirely 3D printed – from smartphone covers to small toys and house apparels. 3D printing allows the creation of physical objects – but in what does it differ from both 4D and 5D printing?

Take Enkey’s tour into a future of new state-of-the-art multidimensinal printers, and discover the technological and manufacture wonders of the world of tomorrow!

What is multi-dimensional printing and how does it work?

Before we delve into the technologic process behind 5D printing, let’s first get some basics on the differences between 3D printing and its 4D and 5D evolutions.

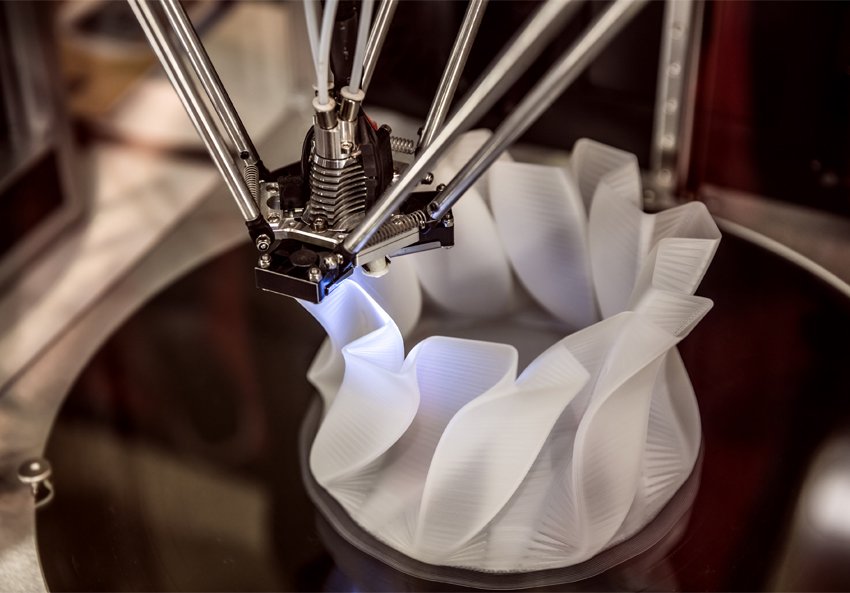

3D printing is widely used nowadays, allowing to craft and create tridimensional items in a variety of materials. The resulting models are both cheap in terms of overall maintenance costs and highly detailed; this process is often used in the printing of internal components at a much faster rate (and cheaper cost) than ever before.

4D printing, on the other hand, shifts the focus on more pliant materials whose appearance might change over time. This change might be prompted by the mere contact with an external element, like air, heat, direct exposure to light, etc. 4D models are by far the most versatile, as their varying structure lends itself to a variety of purposes and circumstances.

For all these reasons, 4D printing is going to play a pivotal role in nedical treatments of new generation. Adaptive prostethics may be entirely 4D-printed; likewise, creating organic material fine-tuned to match the variabilities of human physiology will become not only feasible but easy to achieve. Once more, the advanced technology of tomorrow seems to stem right from the choiciest sci-fi of yesterday.

And what about 5D printing? Before you ask – no, it’s not a printing techniques that breaks past the fifth dimension. The digit rather implies a five-axis print assett, but how does that work? Let’s find out!

5D printing of complex and hollow models

There are relatively few 5D printers out there, but these versatile devices are going to be increasingly popular in the next couple decades.

5D printing allows for a greater variety of complex and intricate models, relying up to five different axis. You might think the processing time takes longer on the overall – but that couldn’t be farther from the truth. 5D printing is both fast and reliable.

But that’s not all, as 5D printing also “fixes” one of the most annoying limits of traditional, mainstream 3D printers.

Printing on five axis allows to create resilient hollow models of the highest quality available.

Whereas a normal 3D printer works on a standard three dimension (X, Y and Z), 5D printers can rely on two additional rotating axis, enabling the cartridge to rotate effortlessly at multiple angles.

The most obvious advantage is that even complex models may be printed single-handedly, trimming off the cumbersome process of assemblage. Even highly intricate components may be printed in half the time and at half the cost.

Discover the five-axis printer that hails from India

5D printing has a momentous potential which we have really only begun to glimpse. But in order for this technology to become really widespread and popular, there is a great need of dedicated five-axis printers.

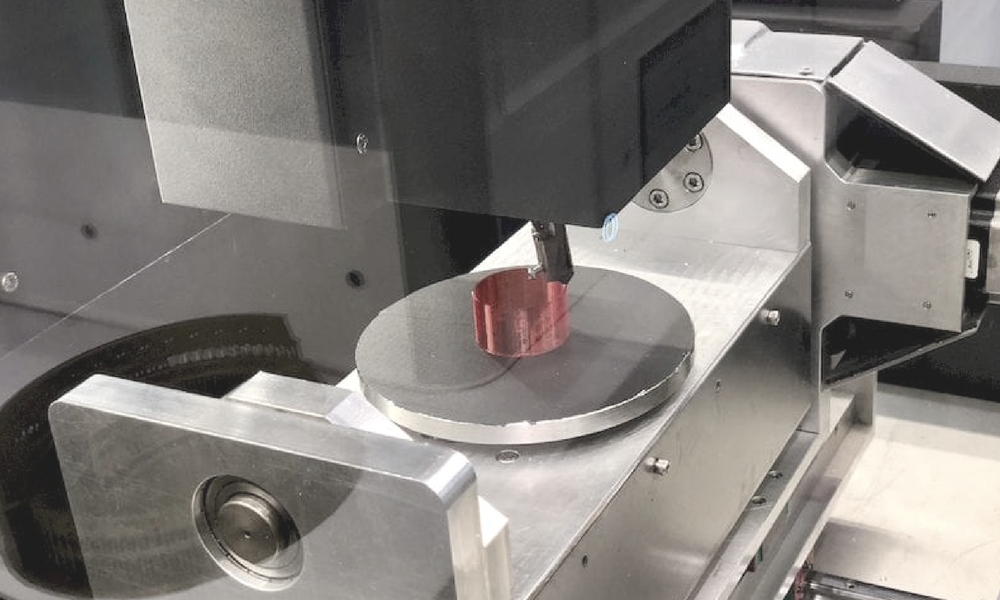

Of all existing models, the Indian Ethereal Halo 5D may be one of the most interesting so far. This printer first debuted at CES 2018, and two years later it might very well head toward changing the world of manifacture industry as we know it.

The Ethereal Halo 5D can print highly complex models in as little as a few minutes. Furthermore, it can cut models and print a variety of materials that may be required to finish a model.

Furthermore, this printer is about 60% cheaper than other similar devices out there.

The Ethereal Halo is produced by Ethereal Machines, an Indian-based company which had already breached the market of 3D printers. CEO Kaushik Mudda, however, firmly believed that 5D was the natural evolution of 3D printing. “Our Ethereal Halo is not a novelty in and of itself, it’s not groundbreaking”, Kaushik explained in an interview. “5 axis printers already existed long before we released our model.”

“Nonetheless, these devices were often extremely cumbersome and expensive. We decided to bet on a desktop-sized version, and involved designers, developers and IT specialists in our project. It was a fun challenge that ultimately brought Halo to life.“

This post is also available in:

Italiano

Italiano